Unibody structures, integral to modern vehicles, require skilled repair techniques for commercial and fleet vehicles, focusing on precision, efficiency, and safety. Advanced tools like CAD software, robotic welding, and VR/AR enhance accuracy and speed in addressing complex structural issues. Best practices, including structured training and diagnostic tools, ensure high-quality repairs, reduce rework, and increase customer satisfaction. These methods contribute to the long-term reliability of fleet vehicles and elevate repair shops' reputations through superior unibody repair techniques.

In today’s commercial and fleet vehicle landscape, understanding unibody structures is paramount for effective repairs. This article delves into advanced unibody repair techniques that revolutionize fleet maintenance. We explore the fundamentals of unibody structures, highlighting their significance in precision repairs. Additionally, we showcase cutting-edge tools and technologies, along with best practices and real-world case studies, ensuring top-quality vehicle upkeep. By mastering these unibody repair techniques, professionals can significantly enhance efficiency and vehicle longevity.

- Understanding Unibody Structures: A Foundation for Effective Repairs

- Advanced Tools and Technologies for Accurate Unibody Repair

- Best Practices and Case Studies: Ensuring Quality in Fleet Vehicle Maintenance

Understanding Unibody Structures: A Foundation for Effective Repairs

Unbody structures form the backbone of modern vehicles, integrating the chassis, drivetrain, and body panels into a single unit. Understanding this intricate design is paramount for effective unibody repair techniques, especially in commercial and fleet vehicle repairs where precision and efficiency are paramount.

Competent auto body restoration involves recognizing the interdependence of various components within the unibody. Skilled technicians at reputable auto repair shops meticulously assess damage, disassemble affected sections, and replace or refurbish parts while maintaining structural integrity. This meticulous approach ensures not only the visual appeal of car paint services but also guarantees the safety and performance of the vehicle post-repair.

Advanced Tools and Technologies for Accurate Unibody Repair

In the realm of commercial and fleet vehicle repairs, advanced tools and technologies have revolutionized unibody repair techniques. These innovative solutions ensure accurate and efficient restoration, addressing complex structural issues common in modern vehicles. One such game-changer is computer-aided design (CAD) software, which allows technicians to precisely measure and analyze damage, facilitating tailored repair strategies. This digital approach not only streamlines the process but also enhances accuracy, minimizing the risk of misalignment or residual deformities.

Additionally, robotic welding systems have emerged as a cornerstone in unibody repair, offering unparalleled precision and repeatability. These technologies complement advanced frame straightening equipment, enabling comprehensive repairs that rival factory standards. Moreover, integration of virtual reality (VR) and augmented reality (AR) tools further enhances auto detailing by visualizing repairs before execution, fostering transparency and customer satisfaction. This holistic adoption of cutting-edge technologies positions modern repair facilities to excel in car collision repair, ensuring vehicles return to their pre-accident condition.

Best Practices and Case Studies: Ensuring Quality in Fleet Vehicle Maintenance

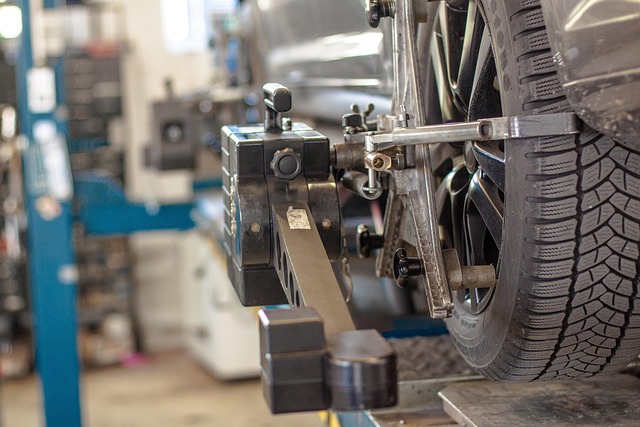

In the realm of fleet vehicle maintenance, best practices and case studies play a pivotal role in ensuring quality repairs. One of the most effective unibody repair techniques involves precision alignment and structural integrity checks. By utilizing advanced diagnostic tools, auto body shops can accurately identify damage and plan repairs accordingly, minimizing downtime for commercial vehicles. Regular training sessions for technicians on the latest unibody repair methods are essential; keeping up with industry standards ensures that each vehicle is handled with expertise, adhering to safety protocols.

Case studies showcasing successful fleet vehicle maintenance programs highlight the importance of standardized procedures and quality control measures. For instance, a leading car body shop implemented a comprehensive system where each vehicle undergoes a meticulous inspection, including non-destructive testing methods, before repairs begin. This approach has demonstrably reduced rework rates and improved customer satisfaction. Incorporating such best practices not only enhances the overall quality of auto body painting and bodywork but also contributes to the long-term reliability of fleet vehicles, fostering a positive reputation for the car body shop among clients.

Unibody repair techniques have revolutionized commercial and fleet vehicle maintenance, offering precise and efficient solutions. By understanding unibody structures and leveraging advanced tools and technologies, technicians can ensure high-quality repairs that extend vehicle lifespans. Implementing best practices and learning from case studies further solidifies the effectiveness of these methods, making them indispensable in modern automotive care.