Unibody repair techniques, integrating chassis and body panels, enhance vehicle safety and structural integrity. Skilled technicians use advanced methods like laser welding and CAD to address bent panels, realigned components, and replaced parts, ensuring safety features are maintained. These techniques, crucial for modern lightweight vehicles, revolutionize automotive safety inspections by identifying and addressing potential weaknesses, providing peace of mind on the road.

Unibody construction, a revolutionary design in automotive engineering, offers enhanced structural integrity and safety. This innovative approach integrates the vehicle’s body and chassis as a single unit, crucial for passing rigorous safety inspections. However, repairing damaged unbodies presents unique challenges due to their intricate nature. This article explores common unbody damage, delving into advanced repair techniques that not only restore structural integrity but also elevate the standards of safety inspections, ensuring vehicles meet modern safety benchmarks.

- Understanding Unibody Structure and Its Significance

- Common Unbody Damage: Causes and Challenges

- Advanced Repair Techniques: Enhancing Safety Inspections

Understanding Unibody Structure and Its Significance

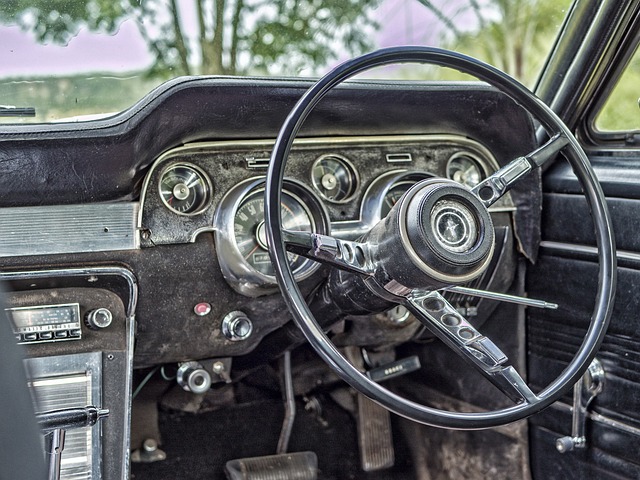

The unibody, a fundamental component in modern automobiles, is a structured framework that combines the chassis and body panels into a single unit. This innovative design philosophy offers numerous advantages, primarily enhancing vehicle safety and structural integrity. By integrating these elements, the unibody provides a robust foundation, distributing crash forces evenly across the car’s frame. This uniform distribution significantly reduces the risk of deformation or collapse during collisions, thereby protecting occupants and improving overall safety standards.

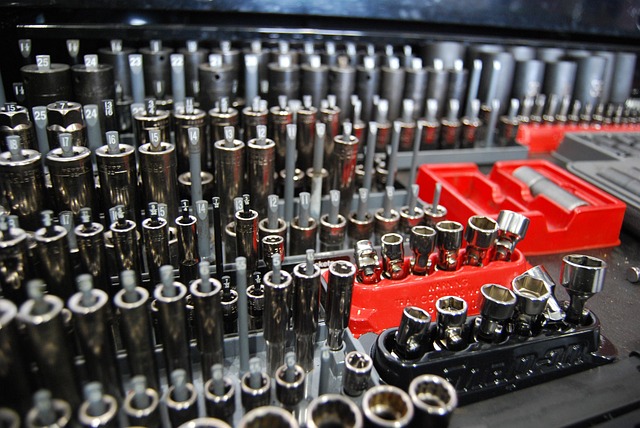

Understanding unibody repair techniques is crucial in ensuring that these structures remain intact and functional after accidents or damage. Skilled technicians employ specialized tools and methods to carefully mend bent panels, realign components, and replace faulty parts, such as auto glass. These repairs not only restore the vehicle’s structural integrity but also maintain its safety features, including the crumple zones designed to absorb impact energy during a collision. Efficient unibody repair practices contribute to successful vehicle body repair, ensuring that cars meet stringent safety inspections and return to the roads with enhanced performance and reliability.

Common Unbody Damage: Causes and Challenges

Unbody damage, also known as structural damage, is a prevalent issue in vehicle accidents and can pose significant challenges during safety inspections. Common causes include high-speed collisions, rollovers, or impact with hard objects. These incidents often result in dents, crumple zones that have exceeded their design limits, and even complete deformation of the car’s frame.

Navigating unbody damage requires specialized auto body services as standard repair techniques may not be adequate. Car restoration specialists employ advanced unibody repair techniques to realign and reinforce damaged panels, ensuring structural integrity. The process involves careful disassembly, precise measurement, and often, computer-aided design (CAD) technology to accurately replace or reshape metal components. This meticulous approach is crucial in maintaining the vehicle’s safety and performance, addressing challenges posed by modern vehicle designs that prioritize lightweight materials and complex structures.

Advanced Repair Techniques: Enhancing Safety Inspections

The advent of advanced unibody repair techniques has significantly boosted safety inspection processes in the automotive industry. These innovative methods, such as precision laser welding and computer-aided design (CAD), enable mechanics to perform intricate repairs with unparalleled accuracy. By meticulously mending damaged panels, from minor dents and scratches to complex structural components like bumpers, these techniques preserve the integrity of a vehicle’s body.

This enhancement in repair capabilities translates directly into more rigorous and comprehensive safety inspections. Auto body services now have the tools to identify and rectify potential weak spots or misalignments that could compromise a car’s overall stability and performance during tests. Consequently, vehicles undergoing these advanced repairs and inspections offer improved safety features, providing drivers and passengers with enhanced peace of mind on the road.

Unibody repair techniques have significantly revolutionized vehicle safety inspections by enabling more precise and effective repairs, ultimately enhancing overall structural integrity. By understanding the intricate nature of unibody structures and employing advanced repair methods, technicians can address common damage types that once posed substantial challenges. This not only ensures better performance during inspections but also contributes to the longevity and safety of vehicles on the road. Embracing these techniques is a step forward in the automotive industry’s continuous pursuit of enhanced safety standards.